A tradition in the past…

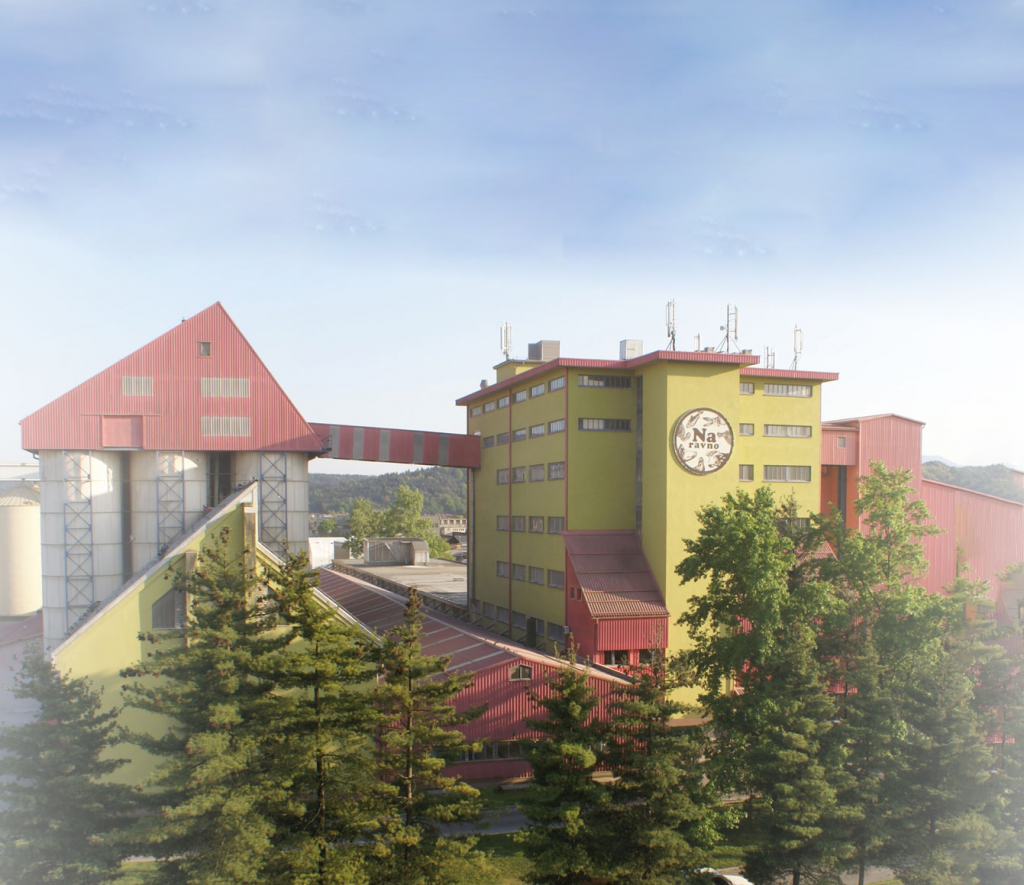

Jata Emona d.o.o. has a 60-year tradition of commercial production of feedstuffs. The feed mill in Ljubljana started operating in 1955.

Jata Emona d.o.o. has a 60-year tradition of commercial production of feedstuffs. The feed mill in Ljubljana started operating in 1955.

Feedstuffs are produced at five locations: in Ljubljana, in Škofja Loka, in Novo mesto, Črnci and in Ljutomer.

Only the highest quality raw materials are used at all locations. A large part of the grains is also of domestic origin and bought directly from Slovenian producers. Our main goals are maximum and stable product quality, timely preparation and dispatch of products to end customers and optimal efficiency and rationality of our production processes.

After-sales activities are important for a successful business, including the provision of expert advice to our customers. The correct choice and use of our feed products and, as a result, an excellent milk, meat or egg production result is the real key to the satisfaction of our customers.

Our consultants are expertly trained and equipped with tools for quick analyses of feedstuffs in the field, for the correct taking of feed samples for laboratory analysis, and based on the results of feed analyses, they are trained to calculate optimal feed rations for animals.

Feedstuffs are produced using the latest environmental protection guidelines. All processes take place in anti-noise closed systems and are connected with dust abatement units, the resulting waste is systematically collected and delivered to concessionaires.

In addition to the precise calculation of important nutrients, feedstuffs are composed also by taking into account recommendations and limitations related to the maximum permitted amounts of individual elements, which, later, during animal husbandry, affect emissions into the environment.

The quality control system in Jata Emona’s feed mills includes chemical analyses of raw materials, semi-finished and finished products both in our own and external laboratories, raw material and feedstuff safety analyses and intermediate controls in the production process.

Only the highest raw materials, checked at the source and then at the very entrance of the feed mill, are used at all locations. A large part of grains is of Slovenian origin.

The entire process, from the acquisition of raw materials to the production and shipment of products, is strictly controlled, ensuring completely unimpaired and safe production and thus the safety and quality of finished products.

The HACCP system has been introduced in all five of the company’s production units and the company is under regular supervision by authorised institutions that control system compliance. Four locations also carry out the production and distribution of “GMO-free” and production of organic feedstuffs. The continuous regularity of all production and distribution procedures for both is monitored by the IKC – the Control and Certification Institute of the University of Maribor (UM), Maribor. The IKC has awarded a certificate according to the “Grown/produced without GMOs” – without genetically modified organisms” and an organic certificate.

Select the catalogue you are interested in by browsing through the categories below.